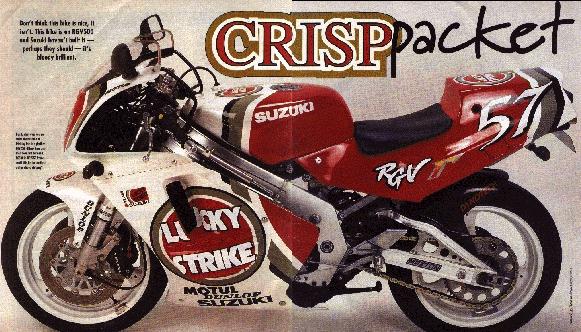

Three years ago I purchased an RG500G from the UK and bought it back to the USA. I wanted a bike that was fast but a lot ligher than the 1992 GSX-R1100 I had at the time and I wanted something slightly unusual too. I rode it for a couple of years and down the road I purchased an RGV250 because I had heard a lot of good things about them. Buying an RGV250 changed my perspective on bikes, it's handling was something that I had not experienced before, I liked it so much I sold my 1100 and bought a second one. I went in to a "small bike", phase, eventually I purchased a third one followed by a GSX-R400RR. The RG seemed to spend more and more time stuck in the back of the garage, mainly because it's handling was pretty shite. My next project was that of updating the suspension and the wheels on the RG to get it's handling up to snuff. I'd heard of people in the UK grafting the RG500 motor in to the RGV chassis which sounded like the dogs bollocks to me but there was nobody who I knew who was capable of doing the swap and besides I had no real info on how to do it. Then in the March issue of Performance Bikes there was an article on a person who had done this swap, I saw it and messed my pants and knew I needed to do it. Early 1996 I was introduced to K.C. Gager the owner of BRG Racing who could do it for me and thus the RGV500 project started.

The main aim of this project is to produce a bike that performs. i.e. a bike with a low weight ideally around 300 Ib's with a high power output 100 bhp+ that handles well and is visually stunning. (Just like me)

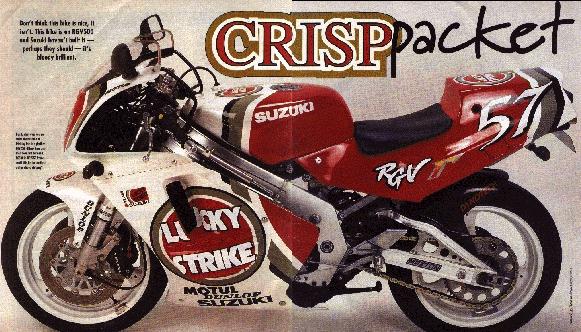

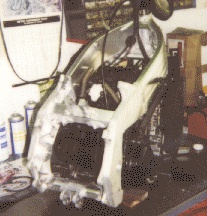

The first part of the process is to remove the engines from both bikes, this has been done, lots of pictures were taken of the frame and engine configurations of each bikes before this was done. The RGV frame is stripped down to a bare minumum and jigs are made. This ensures that when the frame is cut and rewelded everything goes back together straight. The headstock, swingarm pivot, shock mounts, footpeg mounts and subframe mounts are all jigged up. Below are two pictures of the frame with the RG500 motor in it on temporary motor mounts. The right hand side of the frame has been cut away to allow the motor to fit. The cut away parts will be cut out of the frame and replaced with CNC billet parts as will the lower shock/engine mount and upper shock/engine mount.

The RG500 motor is a lot longer and taller than the RGV motor and thus modification of the RGV frame has to take place. We have banded around many ideas. The first idea was to follow what was done in PB, cut the original RGV frame near the swing arm pivot back and weld plate over the webbing on the back to strengthen. Also weld aluminium sheet between to two frame rails to strengthen. (See PB article). An alternative method that we though about was to take whatever was needed off the front of frame and stick it on the back so there was no compromise in strength. I'm told however that the frame may flex slightly differently if both sides are not properly matched. Finally what we decided to do was CNC a complete new rear frame section out of billet. (Frame sides, lower engine/shock mount and upper engine/shock mount) These will be 60% stronger than the cast items they are replacing and 30% lighter. As in the PB article I hope to brace the gap between the frame rails to mount the battery box, coils and powervalve pulley. I'm hoping to get a part manufactured from CF rather than AL, less weight and this will still increase the stiffness of the frame.

Developing the CNC pieces has been a long time consuming iterative process but we have nearly completed them. Below you can see several views of mock up CNC pieces cut from 1" plastic. Black marks around the swingarm pivot indicate minor adjustments that have to be made. The jig can be seen in the top left view which links shock mounts with footpeg mounts. A second jig aligns headstock and swingarm pivot. All parts are heavily pocketed and optimized for strength and lightness.

Front suspension is currently stock RGV, e.g. 41mm USD forks adjustable for preload only, but I've got my hands on a set of GSX-R750 43mm usd fully adjustable items to replace these. This will allow the fitment of a 3.5" front wheel from a GSX-R750. At the back I have a type 3B Ohlins, adjustable for rebound and compression, preload and ride height. I fancied a hydraulic preload adjuster but it wouldn't fit on this shock.

The CDI box is to be modified in order to change the ignition curve. Marc Alexander did the modification for me and from dyno charts this modification is worth about 6hp midrange and 10hp on top.

The carbs will be sent to Tom Crawford for boring ($50 for the set), this will increase the carb bore to around 30.5 - 31mm. The intake tract and disc valves will be matched to the new bores accordingly. I am currently running Rick Lances induction kit which is basically foam filters with a change of main jet to #240 (stock is #120). This will probably change down the road with the carb bore and proper set up as the bike runs very fat and safe at the minute.

Latest news on the carb front is that Marc Alexander and I are going to split the cost of a fuel injection system for the RG500. This may require carrying a larger battery and having the coils rewound to match the power needed to drive the fuel injection system. Marc had just successfully fuel injected a TRX850 with great results.

I've looked at a lot of systems and I settled on a kit from Dennis Foran in Australia, he supplies the pipes in kit form and you weld them up yourself. Two pipes exit on the right side of the bike and two rear pipes exit under the seat they cross over under the seat to get the required tuned length. Of course carbon fibre mufflers are the recipe of the day. To see some pictures of the pipes on another bike click here, here and here.

1 1992 RGV250N ......................... Bought for $5500 1 1986 RG500G........................... Bough and Shipped for $4400 Rick Lances Carb Kit.................... Bought for $ 250 Ohlins Type 3B rear shock............... Bought new $ 650 Dennis Foran Exhaust Kit................ Weld it yerself for $ 225 Dennis Foran Carbon Mufflers............ Bough for $ 465 Jig and cut RGV250 frame................ Labour $1225 43mm fully adjs. usd GSX-R750 forks..... Bough for $ 400 CAD Design of upper engine/shock mount.. Labour/Materials $1145 CAD Design of lower engine/shock mount.. Labour/Materials $1145 CAD Design of right frame section....... Labour/Materials $1145 CAD Design of left frame section........ Labour/Materials $1145 T6061 Billet Aluminium.................. Cost $ 600 RGV250 forks............................ Sold for -$ 250 RG500 clocks............................ Sold for -$ 80 RG500 brake lines....................... Sold for -$ 40 RG500 upper fairing..................... Sold for -$ 50 RG500 left fairing...................... Sold for -$ 100 RG500 left mid fairing.................. Sold for -$ 50 RG500 foot pegs......................... Sold for -$ 25 RG500 gas tank.......................... Sold for -$ 175 RG500 right fairing..................... Sold for -$ 100 RG500 master cylinder................... Sold for -$ 50 Everything else left of RG500........... Sold for -$ 800 Total so far.................................................... $16575