Fuel injection on Yamaha RD500LC

by Olivier PATROUIX (from Rob Koopman emails)

While many manufacturers struggle with two stroke injection

systems, and Egbert Streuer returned to a carburettor setup after lengthy

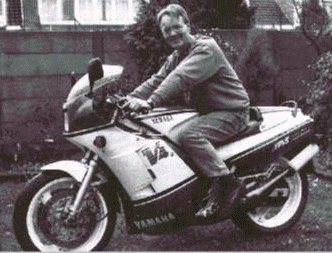

experiments [on his GP sidecar], a driving school owner from Haarlem, Kees

Beekhuis, did succeed in producing a good fuel injection system.

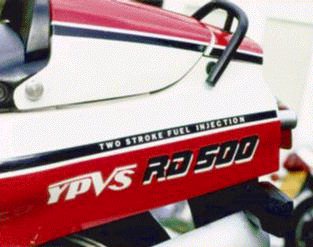

The system has proven itself for more than a year already [It still runs

perfectly now, after 3 years]: his Yamaha RD500LC is not only used for

fast laps at Zandvoort circuit, but also for driving slowly behind his

pupils.

The system has proven itself for more than a year already [It still runs

perfectly now, after 3 years]: his Yamaha RD500LC is not only used for

fast laps at Zandvoort circuit, but also for driving slowly behind his

pupils.

Kees started the project because he wanted more power, without penalising

power delivery, since he need it for his driving school. Buying a different

bike was too easy, he used to race a Morbidelli 125. First he considered

bigger carbs, but he found out they are hard to tune. When the injection

system of one of the cars of his driving school broke down, he decided

to learn about such systems and fix it himself.

Kees started the project because he wanted more power, without penalising

power delivery, since he need it for his driving school. Buying a different

bike was too easy, he used to race a Morbidelli 125. First he considered

bigger carbs, but he found out they are hard to tune. When the injection

system of one of the cars of his driving school broke down, he decided

to learn about such systems and fix it himself.

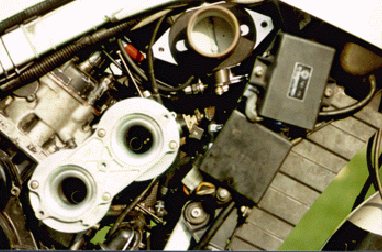

Injection devices

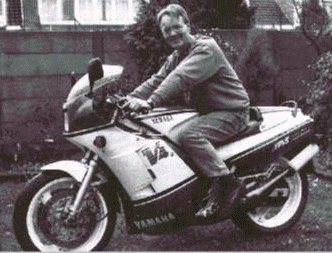

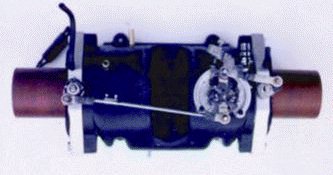

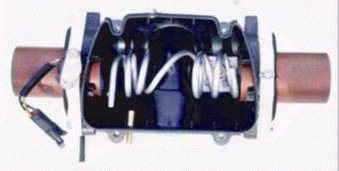

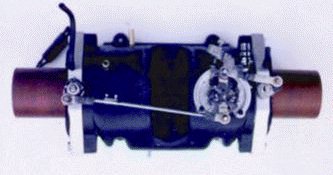

He bought a Motronic system, which served as a basis for the RD project.

Kees used existing components, like injectors, a fuel pump and a fuel

pressure regulator, to constuct his own injection system. Especially the

production of the Black box may be called an impressive achievement. This

unit determines injection timing and duration from a volumetric sensor

using a 'heat wire', a pressure sensor in the inlet and a lambda sensor

in the exhaust. The development of this system took 1.5 years.

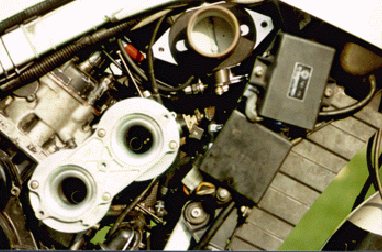

Initially, he did not remove the carbs. He could switch over whilst

riding. But the system proved to be so reliable that he removed the carbs.

The airflow, that was regulated by the flat slides of the carbs, is now

modulated by throttle valves near the airfiltre [!!]

Development problems

Stronger battery needed, ingition affected Black box, inadvertent heating

of fuel due to fuel pump. Beekhuis made a simple fuel cooler, mounted in

the air filtre box. Only one piston was damaged in the development process,

but he used a box full of spark plugs, because he needed to determine the

correct mapping by experiment.

His only aid to determine the optimum mixture was the Lambda-sondeand

a hot wire.

Injection timing was also determined by experiment [30 after BDC].

Injection timing was also determined by experiment [30 after BDC].

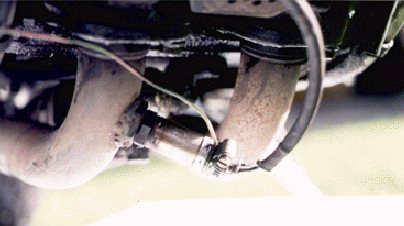

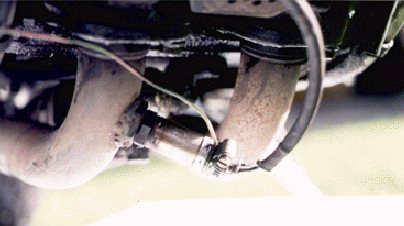

Injection in the cranckcase will inevitably result in a certain throttle

lag, he has made many adaptions to reduce this, e.g. a pressure sensor

in the inlet [the injectors are mounted in the rubber section close to

the membranes], and a throttle sensor that signals rapid opening and closing.

Injection in the cranckcase will inevitably result in a certain throttle

lag, he has made many adaptions to reduce this, e.g. a pressure sensor

in the inlet [the injectors are mounted in the rubber section close to

the membranes], and a throttle sensor that signals rapid opening and closing.

One cannot cut the injection completely in the latter case, because

that would cause huge throttle lag afterwards.

Replacing the carb slides close to the engine by two throttle valves close

to the air filtre reduced throttle lag as well [!!??], but the problem

cannot be further reduced until he revert to injection in the ports.

Replacing the carb slides close to the engine by two throttle valves close

to the air filtre reduced throttle lag as well [!!??], but the problem

cannot be further reduced until he revert to injection in the ports.

During the year that this system is operational, he have'nt had a single

problem and the injection system uses 10% less fuel with at least equal

power and improved power delivery.

During the year that this system is operational, he have'nt had a single

problem and the injection system uses 10% less fuel with at least equal

power and improved power delivery.

He can change the characteristics with a little switch [even the rich (circuit)

setting is still more economic than carbs!

He can change the characteristics with a little switch [even the rich (circuit)

setting is still more economic than carbs!

Rob did a number of laps behind Kees at Zandvoort, the richness of

the mixture was obvious to my nose and eyes, and engine power appears superior

to that of his RG. Kees's bike is equipped with a few LCD readouts, FZR

rims and front brake discs with GSXR 1100 calipers, plus a steering damper.

Kees is really surprised that injection is not more common: four new carbs

for his RD would amount to 2480 guilders ($1260) which is more than he

spent on his injection system" [!!!!]

Seriously, what an effort this must have been! The reliability economy

and power delivery that he achieved surprise Rob a lot. Let's throw away

our carbs! Unfortunately, Kees does not have Internet access :-(.

Return to French RD 500 Club Home Page